Installations / Plants THE SALTING OF MOULDS

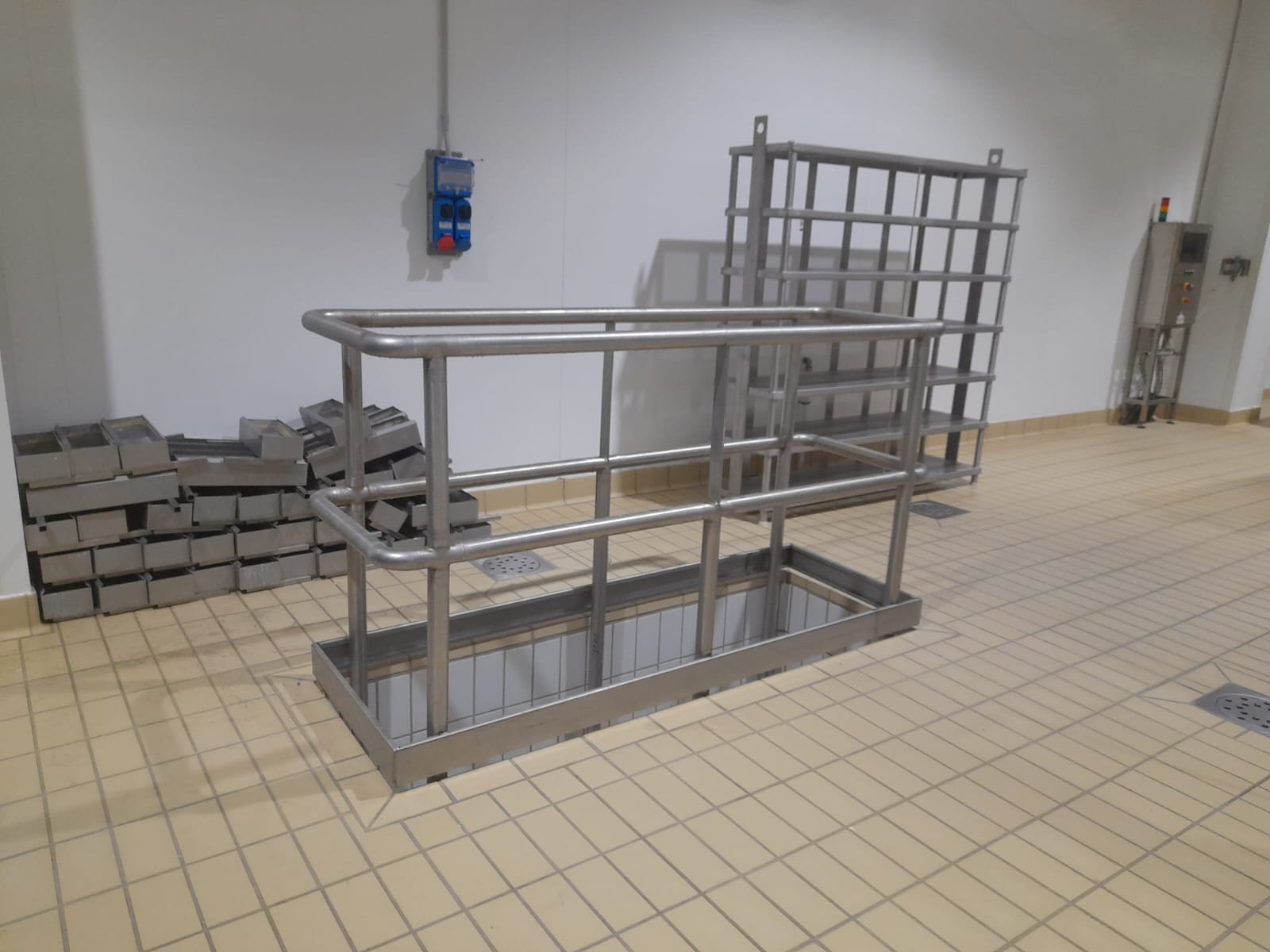

Tecnomeccanica Bellucci designs and creates solutions for the cheese salting process: sanitization of salt pans, systems for automatic or semi-automatic loading of racks, and salt pans.

DYNAMIC SALINES LOADING RACKS OVERHEAD TRAVELLING CRANE HANDLING SALINE SANITIZATION

DYNAMIC SALINES

For cheese factories with high daily loads of handling Parmigiano Reggiano, Grana Padano or other cheeses that require immersion salting, we offer dynamic systems.

With this solution the moulds are immersed in brine via mechanized transport; once in the tank, the generated flow by a pump transports them towards multi-level which are raised and lowered by a lifting baskets system.

The dynamic saltwork is supplied with:

- Independent temperature control and management;

- Automatic recycling of the saline solution;

- Automated maintenance of salt concentration.

OVERHEAD TRAVELLING CRANE HANDLING

The innovative solution we propose implements an automatic movement system of the overhead travelling crane which, through laser measurers and positioners, allows the translation to be stopped in the correct positions so that the operator only has to give the movement command via a special management panel.

ADVANTAGES:

SAFETY

Automatic movement prevents inaccurate or hasten operation which can overturn the load and bang against the tank’s walls, columns or masonry parts.

TIMES

Repeated manual adjustments of the position which create load oscillations and significantly slow down the immersion of the cages are avoided.

SALINE SANITIZATION

Ultrafiltration or microfiltration system with membranes to keep the brine free from mould, suspended residues and bacteria that cause bad smell and pollute cheese water.

The plant is able to work continuously and guarantee a stable brine quality over time which defines constant cheese quality.

The process takes place cold therefore energy consumption is low.

Contact us

Request personalized advice for your food industry