Installations / Plants THE MOVEMENT OF MOULDS

Tecnomeccanica Bellucci designs and creates solutions for the lifting and handling of form: bundle transport, battery-powered flipper, immersion anti-mold, plastic coat.

TRANSPORT OF BUNDLES BATTERY OVERTURN IMMERSION ANTI-MOLD

TRANSPORT OF BUNDLES

Trolleys with electric motors for lifting and transporting bundles.

Motors are operated with low voltage direct current and powered by high-performance lithium batteries.

Control system managed via wi-fi connection which allows trolleys to move in complete autonomy.

The operator can determine the trolley path by choosing the route to the unloading or the route that avoids occupied boilers by the processing.

ADVANTAGES

SAFETY

improvement of working conditions and operator safety

TIMES

optimization of unloading times and cost efficiency

SPACE

optimization of floor space for cooking room movement

RESOURCES

less staff at unloading, gain of resources for higher value-added activities

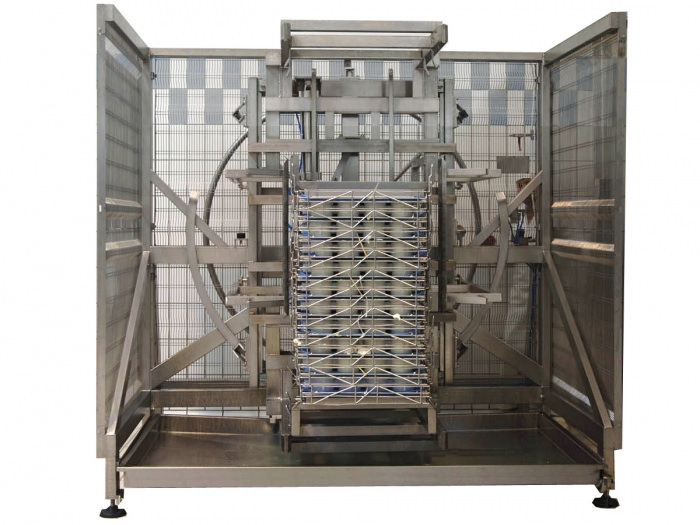

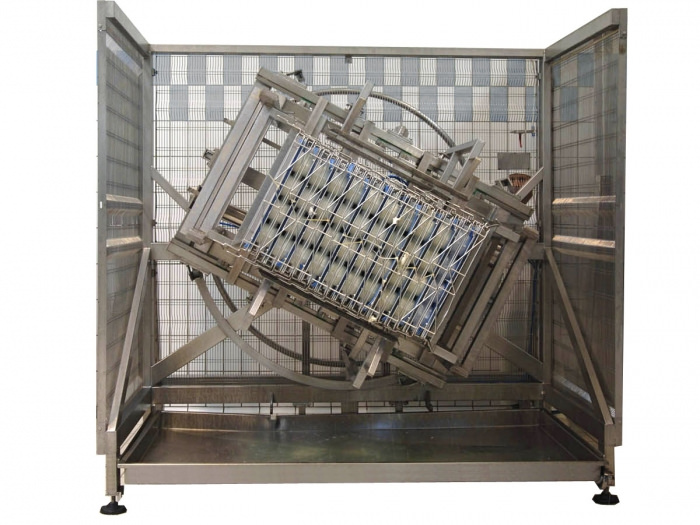

BATTERY OVERTURN

Designed for overturn multiple stacked moulds; it can have manual or completely automatic movement.

ADVANTAGES

SAFETY

Poperator protection guaranteed by peripheral panels and electronic devices

EFFICIENCY

the overturn-rest-overturn cycle allows the whey extraction and optimal self-pressing

IMMERSION ANTI-MOLD

Automatic equipment designed for anti-mold treatment application by immersing the forms; built entirely in AISI304 steel, capacity of 1,600 mould/hour.

ADVANTAGES

EFFICIENCY

continuous immersion of cheeses through a conveyor; potential 1600 mould/hour

QUALITY

protection of the cheese against fungus during consecutive processes and/or preservation.

Contact us

Request personalized advice for your food industry